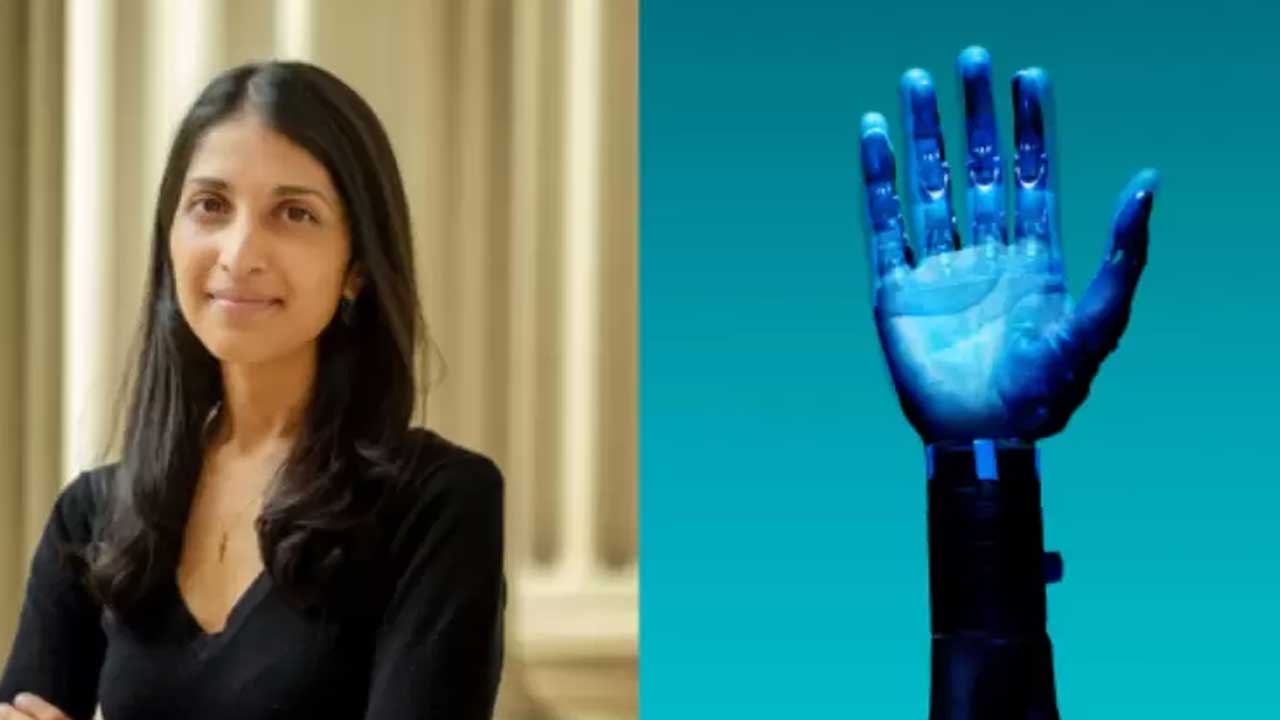

Cambridge, Massachusetts, USA: Indian American engineer Ritu Raman and her team at the Massachusetts Institute of Technology (MIT) have created artificial tendons that markedly improve the strength and speed of muscle-powered robots, offering exciting possibilities for future biohybrid machines.

Published in Advanced Science, the study details how the team engineered tendon-like connectors from durable and flexible hydrogel. These connectors were attached to lab-grown muscle to form a “muscle–tendon unit.”

When integrated with a robotic gripper, this unit allowed the robot to close its fingers three times faster and exert 30 times more force compared to designs that relied on muscle alone.

“We are introducing artificial tendons as modular connectors between muscle actuators and robotic frameworks,” said Raman, an assistant professor of mechanical engineering at MIT. “This approach could simplify the creation of diverse robotic systems, ranging from tiny surgical instruments to adaptive, autonomous exploratory robots.”

Biohybrid robotics combines living muscle tissue with synthetic structures, but has historically been limited by muscle softness, difficulty in anchoring tissue to rigid frameworks, and the modest force produced by muscle contraction. Raman noted that traditional methods often waste muscle mass simply to secure tissue to robotic skeletons.

The team leveraged hydrogel, engineered at MIT for strength, stretchability, and adhesion. They modeled tendon stiffness to optimize gripper movement, then produced thin hydrogel cables linking both the muscle tissue and mechanical components.

Tests demonstrated that the artificial tendons enhanced the robot’s power-to-weight ratio by 11 times and maintained performance over 7,000 contraction cycles. Additionally, the tendons prevented muscle tearing and efficiently transmitted force between soft and rigid parts.

“You only need a small actuator that is cleverly connected to the skeleton,” Raman explained.

Experts described the research as a meaningful advancement toward biohybrid systems capable of functioning reliably outside laboratory conditions. Simone Schurle-Finke, a biomedical engineer at ETH Zurich, said the design “substantially improves force transfer, durability, and modularity.”

Raman’s team is also working on complementary components, such as skin-like protective layers, to help muscle-powered robots perform in real-world environments.

Funding for the research came from the U.S. Department of Defense Army Research Office, the MIT Research Support Committee, and the National Science Foundation.